Thermal Spray Coating

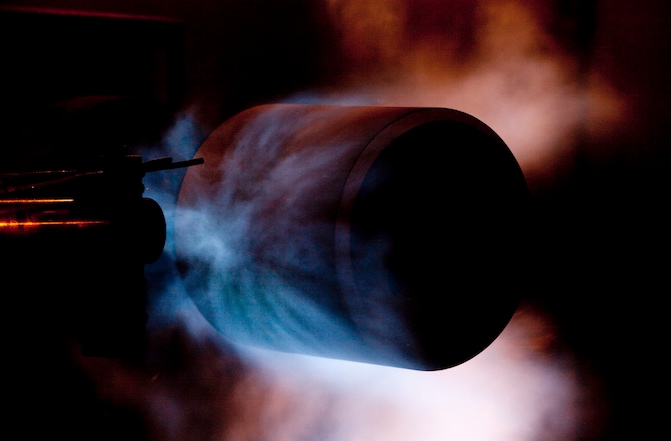

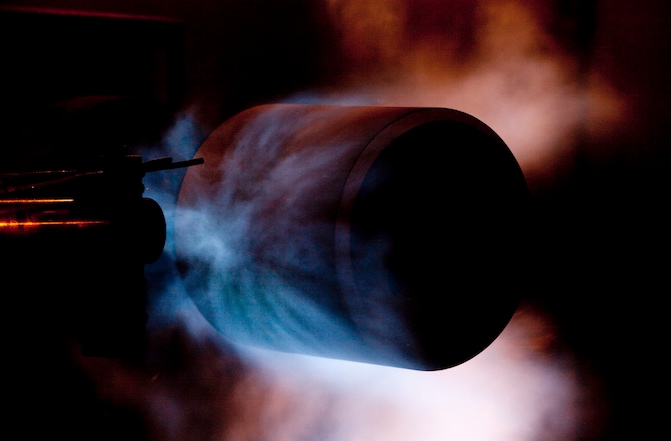

Cost-effective and versatile options including D-GUN™, HP/HVOF®, wire arc and plasma spray for coatings that resist wear, corrosion, fatigue, oxidation and more.

EXOGARD™ Coatings

The right coating can perform to its highest potential only when applied correctly. Linde has developed and patented a wide range of application methods to optimize the performance of our high-quality coating materials. Together, advanced materials and precision application processes ensure coatings with the bonding, wear and resistance characteristics you need are delivered reliably and consistently. Linde coating processes have been engineered to help improve efficiency, reduce cost and mitigate risk in operations. Choose from an array of application options to meet requirements, from bulk processing to specialty coating.

Cost-effective and versatile options including D-GUN™, HP/HVOF®, wire arc and plasma spray for coatings that resist wear, corrosion, fatigue, oxidation and more.

EXOGARD™ Coatings

Choose from three distinct processes designed to deliver the coating properties and structured precision parts demand.

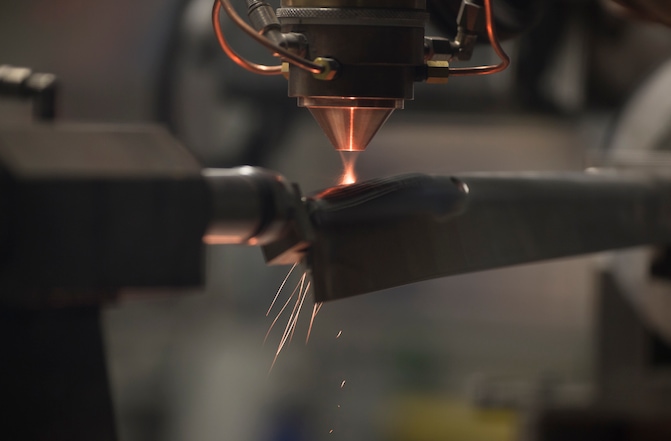

Laser-engraved ceramics for flexographic and gravure printing. Impervious laser clad overlays for protection of components from heavy wear and corrosion.

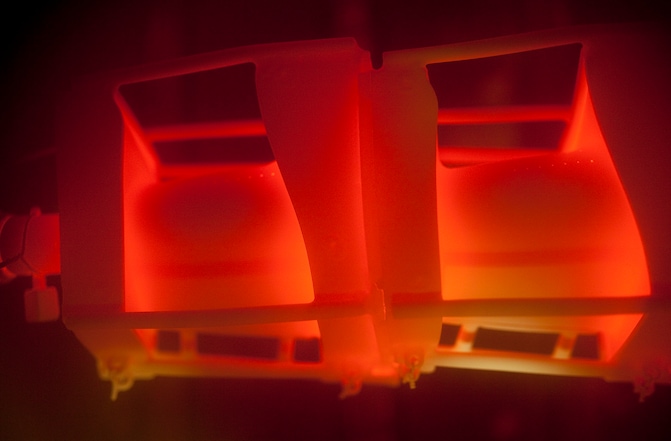

Protecting high-temperature parts from corrosion and oxidation, providing a protective barrier by diffusing a metal and forming a new alloy surface.

A good fit for complex geometries, our patented Tribomet™ process produces dense, non-porous coatings and maximizes the wear resistance of critical components.

Application methods, including brushing, dipping, flowing and spraying, result in stable coating films and strong bonds to substrates.