Meeting Operational Challenges

Advanced Material Solutions by Industry

Answers That Go Deeper

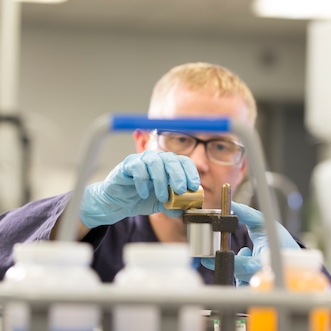

Innovative Materials Engineered for Your IndustryThe right material solutions do much more than protect components or aid in manufacturing. Well-designed material technologies also enable uptime, reduce maintenance, control costs and drive processes. Linde has the experience to understand how material technologies serve your business, helping you optimize performance and improve end products and operations. Learn more about how our advanced materials and services are made to meet your demands and deliver results.

Aviation & Aerospace

Advanced materials and services that meet rigorous specifications to help your operation remain innovative and competitive.

Coating Services for the Aviation Industry

Clean Energy Production

Lightweight, durable materials that support advanced energy production with greater efficiency and performance.

Surface Solutions for Lithium-Ion Battery Equipment

Power Generation

Practical solutions to control corrosion, wear and fouling, plus technology and processes that limit turbine downtime.

Oil & Gas Production

Made to handle the relentless pressure of recovery and production, to extend part life and maximize uptime.

Manufacturing & Industrial

Materials and processes designed for repeatable results, for parts that perform as expected run after run.

Semiconductors & Electronics

A reliable supply of high-purity metals and application options to meet growing demands in communications, computing and more.