Aluminum Oxide Coating in Manufacturing and Industrial Applications

Discover how aluminum oxide coatings enhance durability, reduce maintenance costs, and improve efficiency across manufacturing and industrial sectors.

Engineers in advanced manufacturing seek materials that can withstand extreme operating conditions, paving the way for ceramic material solutions. These specialized coatings help extend equipment lifespans, reduce maintenance costs, and improve operational efficiency across diverse industrial sectors.

Related: What is tungsten carbide?

What is Aluminum Oxide?

Aluminum oxide (Al₂O₃) or Alumina coatings are widely used in industrial and manufacturing applications due to their excellent wear resistance, hardness, and thermal stability. Applying this chemical compound creates an extremely dense, chemically inert aluminum oxide layer that delivers superior protection. Additionally, these coatings provide electrical insulation, corrosion resistance, and are chemically inert, making them ideal for harsh environments.

Thermal spray processing offers a versatile means of depositing alumina coatings onto various industrial components and surfaces. Selecting the right process technology and refinement of parameters is critical to achieving optimal aluminum oxide coating performance.

Related: What is zirconium oxide?

Advanced Application Methods for Aluminum Oxide Coatings

Linde Advanced Material Technologies (Linde AMT) offers the following thermal spray processes to deposit high-quality aluminum oxide coatings. Our materials scientists and application engineers work closely with customers to select the right process and optimize coating solutions for specific operational challenges, ensuring maximum component protection and longevity.

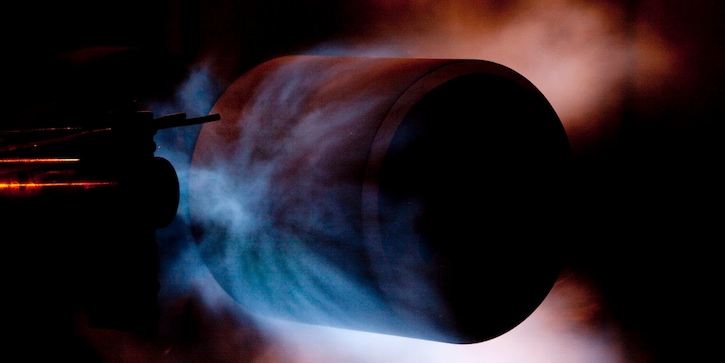

Plasma Spraying

Our most versatile application method for aluminum oxide coatings injects the material into a high-temperature plasma plume, melting and accelerating it toward the substrate. This creates exceptionally dense coatings with superior bonding strength while remaining economical for coating large components. Our plasma-sprayed aluminum oxide coatings deliver:

- Precise thickness control

- Excellent adhesion to substrates

- Consistently uniform coating structure

- Superior dielectric properties

- Cost-effective application

Detonation Gun (D-GUN™) Spraying

Our proprietary D-Gun™ technology harnesses controlled detonations to accelerate molten aluminum oxide particles to supersonic velocities. The result is an extremely dense coating with:

- Minimal porosity

- Exceptional adhesion strength

- Superior wear resistance

Combustion Spraying

Our combustion spray technology delivers aluminum oxide coatings economically for large-scale applications. This process combines fuel and oxygen to melt and propel coating particles, resulting in:

- Excellent coverage on large surfaces

- Good wear resistance properties

- Consistent coating quality

- Remarkable uniformity across complex geometries

Key Benefits of Aluminum Oxide Coatings

Enhanced Wear Resistance

Aluminum oxide coatings provide exceptional protection against abrasive and erosive wear. The coating's high hardness and excellent substrate adhesion create a durable barrier that extends component life, particularly in applications involving particle impingement or sliding wear.

Corrosion Protection in Harsh Environments

Aluminum oxide's chemical stability makes it ideal for protecting components exposed to aggressive chemical environments. These coatings maintain their protective properties across a wide pH range and resist degradation from oxidizing and reducing agents.

Electrical Insulation

Aluminum oxide coatings are extensively used as an electrical insulator for components. Due to their high hardness and refractory nature, they are also used to provide dielectric properties at elevated temperatures.

Linde AMT's Aluminum Oxide Coating Solutions

Our comprehensive range of aluminum oxide coating formulations addresses specific industrial challenges:

- Pure Alumina - Offers wear and abrasion resistance. It is also inert to common acids and alkalis.

Use cases: industrial rollers (printing and textile), chemical vessels, pump components, abradable coating in jet engine clearance control, high temperature environments - Premium Alumina - Deposited using high purity (99.99%) feedstock combined with Linde AMT’s proprietary plasma technology for exceptional electrical insulation benefits.

Use cases: electrostatic chucks for semiconductors, insulated bearings, other applications requiring superior dielectric properties. - Alumina-Titania - Provides a combination of enhanced wear resistance and toughness through titania additions.

Use cases: corona rolls, glass rolls, seal teeth for gas turbine engines, wear-resistant tooling

Why Choose Linde AMT?

With over five decades of materials expertise, Linde AMT delivers aluminum oxide coating solutions that consistently outperform industry standards. Our approach integrates:

- Materials Science Expertise - Our team develops precisely engineered powder formulations optimized for your specific application requirements.

- Application Technology Leadership - Our advanced thermal spray systems achieve coating properties that generic solutions cannot match.

- Comprehensive Technical Support - From initial material selection through coating optimization, our engineers work with you to maximize component protection and operational performance.

- Quality-Focused Production - Our rigorous quality control processes ensure coating consistency and reliability for the most demanding applications.

FAQs

What is aluminum oxide used for?

Aluminum oxide coatings are a critical protective barrier for industrial components exposed to extreme wear, high temperatures, and corrosive environments. They are commonly applied to protect aerospace engine parts, textile machinery components, and chemical processing equipment.

Are all plasma-sprayed alumina coatings the same?

No. Coating quality varies based on powder purity, particle size distribution, spray parameters, and post-processing techniques.

How does substrate material affect coating adhesion?

While aluminum oxide coatings can be applied to most metallic substrates, optimal adhesion is achieved on materials with similar thermal expansion coefficients. Our engineering team can recommend appropriate bond coat solutions for challenging substrate materials to ensure lasting performance.

Can aluminum oxide coatings be applied to complex geometries?

Yes. Linde advanced coating systems and specialized application techniques allow precise coating application on complex shapes and internal surfaces, though some geometric limitations may apply depending on the component.