Thermal Spray Torches: Advanced Coating Equipment

Discover the basics of thermal spray torches and their role in industrial coating processes. This article explores TAFA® thermal spray torches by Linde AMT, used in aerospace, automotive, energy, and more.

In the dynamic world of industrial manufacturing, achieving excellent surface properties is crucial for improving component performance and durability. Thermal spray technology has become a key solution, offering advanced coating capabilities that meet the demanding needs of modern industries.

Linde Advanced Material Technologies (Linde AMT) leads this innovation with TAFA® thermal spray torches designed to enhance coating applications across sectors such as aerospace, automotive, energy, semiconductor, and others. This article covers the basics of thermal spray coating equipment systems and how these advanced equipment solutions transform industrial coating processes.

Introduction to Thermal Spray Technology and Torch Systems

Thermal spray guns are advanced tools used in the thermal spraying process to apply coatings onto surfaces at high temperatures. These precise devices are essential in various industries to improve component performance, durability, and corrosion resistance.

Understanding Thermal Spray Fundamentals and Process Applications

Thermal spraying involves melting metallic or non-metallic materials, propelling them onto surfaces, and forming a protective layer. This process greatly increases the lifespan of components, enhances surface properties, and effectively repairs damaged parts. Thermal spray guns apply materials like metals, ceramics, and polymers to create the desired coatings.

Evolution of Thermal Spray Torch Technology in Modern Manufacturing

Over the years, thermal spray torch technology has improved greatly to meet the growing demands of modern manufacturing. With their TAFA® Thermal Spray Coating Equipment's, Linde AMT has developed advanced thermal spray systems that deliver superior performance, accuracy, and efficiency. These torches offer customizable options and modular designs to suit specific industrial needs.

Key Industries Benefiting from Advanced Thermal Spray Solutions

Various industries benefit from using thermal spray coatings with advanced torch systems. Manufacturing, aerospace, automotive, semiconductor, and energy sectors depend on thermal spray technology to protect components from wear, erosion, and high temperatures. Thermal spray solutions improve operational efficiency and boost the overall performance of critical equipment.

Types of Thermal Spray Torches

Plasma Spray Torches

Plasma spray guns are advanced tools that use a high-velocity plasma jet to melt and project materials onto surfaces. They are perfect for applying coatings that need high temperatures and accuracy, such as ceramics and refractory metals.

High-Velocity Oxy Fuel (HVOF) Torches

HVOF spray torches commonly apply wear-resistant coatings on various surfaces. These methods effectively coat base metals, alloy powders, and fluxing alloys to improve surface properties.

Arc Spray Torches

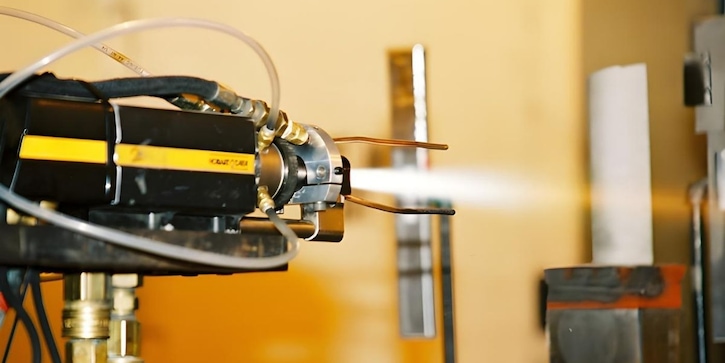

Arc spraying is an economical thermal spray method, recognized for its sturdy pull-wire feed system, making it suitable for quickly coating large areas with uniform quality. The process operates at lower particle speeds, allowing for the efficient buildup of thick coatings in minimal time.

Discover our thermal spray torches

Material Compatibility

Choosing the right thermal spray torch and material ensures compatibility and produces top-quality coatings. Understanding the properties of different powders, gases, and substrate materials is key to optimizing coating performance and lifespan.

Learn more about our thermal spray powders

FAQs

What are the benefits of using thermal spray torches over traditional coating methods?

Thermal spray torches produce coatings with specialized properties, such as electrical conductivity, high temperature, or wear resistance, which can be difficult to achieve with traditional coating methods. They excel at precision, enabling targeted application with minimal overspray, reducing material waste, and improving the accuracy of the coating process.

How can I determine the most suitable thermal spray torch for my application?

Choosing the right thermal spray torch for your specific application involves assessing several important factors. First, the compatibility of the coating material with the thermal spray process is essential, as different materials may require different types of torches, such as plasma, HVOF (High Velocity Oxygen Fuel), or wire arc, to produce optimal results.

Are there any maintenance tips for prolonging the lifespan of thermal spray torches?

Regularly cleaning the nozzle and air cap is vital to prevent buildup that can weaken the torch's efficiency and lifespan. Properly aligning all torch parts is just as important, as it helps achieve optimal spray patterns and reduces wear on the components. Choosing the correct type and mixture of fuel gas and oxygen is essential for maintaining the device's efficiency and longevity.

Read more on our thermal spray equipment maintenance services